The use of Computer Aided Design (CAD), Finite Element Analysis (FEA), and Computational Fluid Dynamics (CFD) for Engineering Design Optimization provides tremendous added value to the product design process. The use of these tools is a major factor in reducing design costs by allowing numerous simulations to be performed using computer software in the time that it would take to build and test a single or a few iterations of a concept or prototype.

What is Engineering Design Optimization?

Engineering Design Optimization is the use of optimization techniques to achieve design goals in engineering or product development. It is often used for structural design, thermal design, shape optimization, aerodynamic/hydrodynamic efficiency, and surface/topology optimization. A few examples of products that often require engineering design optimization include beams, pressure vessels, airfoils/hydrofoils, and heat exchangers.

The Importance of Optimizing Engineering Designs

Engineering Design Optimization is most critical during the initial stages of design. Performing optimization allows a product development engineer to optimize the trade space between such parameters as weight, cost, strength/deflection, resonant frequency, while considering spatial dimensions/constraints, external loads, material, and manufacturability. When products are designed without considering the entire trade space, the solution tends to exhibit one or more over-engineered parameters.

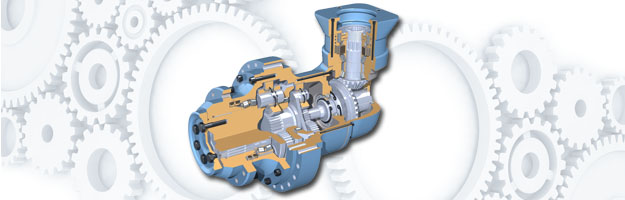

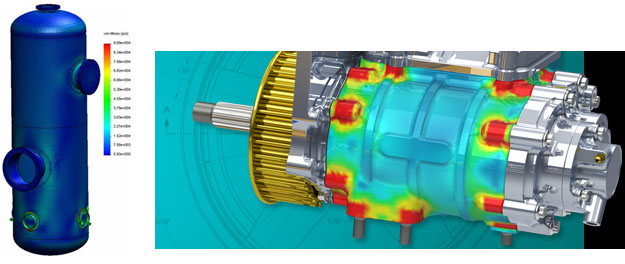

Mechanical and thermal effects and loading scenarios are often evaluated using FEA. A CAD model used with an FEA analysis tool is the best way to quickly evaluate a range of physical conditions. Different geometries and material properties can be tested rapidly to identify the best suitable candidate material for a design.

The Application of CAD and FEA in Engineering Design Optimization

Some of the common uses of CAD and FEA in Engineering Design Optimization include:

- Static structural analysis is often conducted to ensure that the components are designed with a sufficient factor of safety to withstand the static/weight bearing mechanical loads and stresses to which the system is exposed.

- Dynamic structural analysis may be conducted to ensure that the components survive sudden shocks, impacts, or high levels of vibration. This can also be used to determine natural resonant frequencies to prevent failure under dynamic loading conditions.

- Weight optimization is conducted by iterating through various geometries and material properties to identify the optimal design that minimizes weight within the constraints of the structural, thermal, and cost requirements for the system/component.

- Thermal optimization is conducted to determine the necessary geometry to provide sufficient heat transfer for heat sink components.

- Hydrodynamic efficiency optimization investigates hydrofoil geometries to provide low hydrodynamic resistance while maintaining ship or submarine stability.

- Aerodynamic efficiency optimization investigates airfoil geometries to maximize lift or thrust while minimizing weight.

Depending on the product, one or more of these analyses may provide valuable improvements a design. The earlier in the design process, the more effective they are as it becomes more difficult to change the design as the product matures. Weight optimization is often the exception, as it is not uncommon for a product to exceed its weight requirements due to over-engineering and require a design optimization for weight at the end of the development cycle.

Examples of Engineering Design Optimization in Industry

The introduction of a formal Engineering Design Optimization strategy early in the design process has proven successful in many industries. The classic example of Engineering Design Optimization is in the aerospace industry. While it is natural to assume that the problem is one of simply minimizing weight component by component, the problem is more complex, as the need to maximize strength, maximize aerodynamic efficiency (lift and thrust) and minimize cost of fabrication are important parameters. CAD models are used extensively with FEA and CFD to solve this problem from both a structural and aerodynamic perspective. Without these tools, the optimization problem is extremely daunting.

Military and Biomedical Applications

Engineering optimization has led to lightweight composites for military and biomedical applications. The weight of military equipment effect transportation cost and operator fatigue greatly. Weight reduction of a soldier’s equipment has reduced burden and improve maneuverability. In the past, most components were over-engineered due to a lack of viable materials. The introduction of Kevlar, carbon fiber, fiberglass and other composites have revolutionized the industry Weight reduction in prosthetics, artificial limbs, joints, braces and other biomedical devices have greatly improved mobility giving patients a new life.

Space-Age Plastics

Technological advances in space-age plastics have facilitated design optimization of prostheses that are considerably lighter, stronger and more durable than the previous generation of artificial limbs. Without CAD, FEA, and CFD to accelerate design optimization, these products would never have reached their current technological maturity. Far more interesting is the conceptual designs that will revolutionize the future that are years, or decades from fabrication.

A prime example is the Sky Whale, a concept airplane with an 88 meter wingspan that houses 755 passengers. The aircraft was designed by Spanish designer Oscar Vinals, features three stories with three passenger classes, virtual reality windows, 45-degree tilting wings for immediate take-off, and self-healing wings. The design also boasts a feature that causes the passenger section to detach from the wings in the event of a crash landing to reduce the chance of loss of life.

To satisfy this challenging design optimization problem, advanced materials made up of alloys, ceramic/fiber composites, or carbon nanotubes would be used. A hybrid turbo-electric propulsion system is also required for the active wings with higher efficiency than conventional jet engines. While this aircraft is far from entering our reality, it may very well prove to be one of the most revolutionary designs that used CAD, FEA, and CFD to provide a revolutionary breakthrough that will resemble something otherwise seen only in a Transformers movie.

Conclusion

Optimization allows engineering companies to get the most out of a given product they design or wish to design. It minimizes waste and improves productivity. For example, we at ICW recently optimized the design of a Lumbar Support helping patients with severe back problems, which reduced the cost of manufacturing by 30%. Optimization thus promotes the advancement of innovative application of CAD, FEA and CFD in manufacturing.

– IndiaCADworks

IndiaCADworks