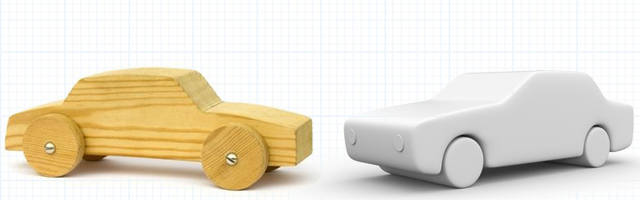

Today’s engineer lives and thrives in a 3D CAD model world. CAD models provide design versatility and a direct link to rapid prototype development. As a result, our libraries of CAD models are ever more important. Reverse engineering using 3D scan data is a fast and efficient way to generate CAD models when an object exhibits a complex shape or when a 3D model does not exist for a component. 3D scanning equipment captures the physical geometry of a component and transforms it into a 3D digital model.

Reverse engineering can be used to:

- Obtain CAD data that captures an object’s original design intent

- Design a new part to fit to a legacy part

- Accurately model performance surfaces

- Update CAD models of your tooling to match shop-floor changes

- Redesign a part without manufacturing defects

- Modernize your manufacturing process

- For animation or visualization

- To perform dimensional and comparative analysis of an object

- For performing FEA or CFD analysis

- To digitally reconstruct a damaged part so that it can be reproduced in its originally intended form using rapid prototyping or CNC technologies

3D scanning technologies come in many shapes and forms. Some are stationary, requiring the part to be brought to the scanner. Scanning laser technology then surveys the 3D contour of the surface and saves the geometrical data to a CAD model. 3D scanners have been used to scan vehicles, airplanes, historic monuments, ships, submarines, buildings, monuments, sculptures, consumer products, to name a few.

An example of a complex 3D scanning problem is the 3D scan generation performed by Creaform using their HandyScan3D handheld unit in combination with a long-range scanner of the United States Marine Corps War Memorial replica, located at the Marine Corps Recruit Depot in South Carolina. The purpose of the project was historical preservation so that the memorial could be recreated in the future if it were ever to suffer damage. The handheld scanner used for this application is capable of scanning ½ million points per second with up to 30 sq.m resolution accuracy and 60 sq.m volumetric accuracy.

How do 3D scanners work?

Laser scanning passes a laser line over the surface of an object. Surface data is captured by a camera sensor mounted in the laser scanner which records and saves three-dimensional information to a model. Regions of an object are scanned at once, allowing hundreds or thousands of closely positioned points to be surveyed at once. Several types of laser scanners exist, including line, patch, and spherical. Laser scanning is performed without making contact with the object. Digitizing is a contact based form of 3D scanning in which a point or ball probe is scanned over points on the surface of an object to record geometrical position information. Digitizing is more accurate for industrial reverse engineering applications when precision of a complex part is desired, whereas 3D laser scanning is far more desirable for non-standard or organic shapes such as sculptures or a person’s face. Digitizing is often limited to smaller objects, while 3D laser scanning is more versatile, and can be used to scan large objects, such as vehicles or buildings. White light scanning, CT scanning and photo image based systems are alternate methods that are being used for 3D scanning applications.

Limitations of 3D Scanning

- Bright white light sources can be detrimental to 3D scanning technologies, requiring many outdoor laser scanning projects to be conducted after daylight hours.

- 3D scanning works better on matte finishes than highly reflective surfaces, which reflect white light. Spray on solutions exist that can effectively dull a surface prior to scanning.

- Some intricate objects, such as large sculptures, require the use of stationary and handheld scanners to reconstruct the entire surface. This process requires detailed and intricate image and position registration – fortunately, many companies exist that have mastered this process and provide solutions for these difficult problems.

Inspection Using 3D Scanning Technologies

Inspection is another valuable use of 3D scanners, allowing parts to be rapidly checked to ensure that manufacturing tolerances have been met. 3D scanning technologies are commonly used in First Article Inspection, where high accuracy and extremely fine resolution are required in order to verify that a physical part has been produced according to production drawings. Scanners can also inspect a “final” part so that final part models and drawings can be generated for use as blueprints and for re-manufacturing a part. Inspection of aging components or systems is also possible using these technologies. For aging ships or aircraft, for example, or when modifications are required to update the vehicle, reverse engineer using laser based 3d scanning technologies can produce the physical dimensions of the vehicle or its parts.

A prime example is reverse engineering an F-15 test plane for NASA engineers conducted by Direct Dimensions, Inc. (DDI) in 2006. The engineers at NASA desired to modify the test plane and obtain in-flight data to verify their design improvements. Due to the daunting costs associated with full-scale testing, and the danger associated with measuring pressure on a plane moving at supersonic speeds using a chase plane, they chose to reverse engineer the plane so that they could simulate the design changes using computational fluid dynamics (CFD) software prior to implementation and testing.

DDI used the FARO LS 3D laser system, a portable scanner designed for scanning the shape of large objects, capable of acquiring up to 120,000 points per second over ranges of up to 80 meters. This technology allowed DDI to quickly and accurately capture the exterior shape of the jet with an accuracy of +/-6 millimeters. The raw 3D scan data provided a high-resolution point cloud of laser-reflected spots off the plane’s surfaces that were digitally processed and converted to CAD format. Over 50 individual scan from different positions were used to generate over 50 million data points that were used in reverse engineering the F-15.

– IndiaCADworks

IndiaCADworks