When 3D printing first broke onto the scene and started to gain traction, entering into the public consciousness, there were limited, niche applications available. Scientists, universities, and industries who could afford them for the emerging needs were the only places you found 3D printers.

However, in the years since, 3D printing has become much more affordable and with 3D printing CAD file creation service providers, it requires significantly less cost and knowledge at the business level. The use of 3D printers still feels like a futuristic technology that’s unlocking new possibilities, and that’s set to continue as different industries continue to find new applications and businesses themselves are transforming the way they operate to adapt to this new world of 3D printing. The speed, versatility, and affordability of creating a physical product through 3D printing are unbelievably empowering for the innovative businesses that opt to think outside the box.

What Is 3D Printing and What Are Its Applications?

To start, it’s important to really understand what exactly 3D printing is and how the technology has enabled new applications. Despite only being very accessible and prominent in recent years, the technology has actually been around in some form or another since the 1980s. But more recently, the technology has gotten smaller, more affordable, and more usable; that’s why you hear more and more about 3D printing across different industries and applications.

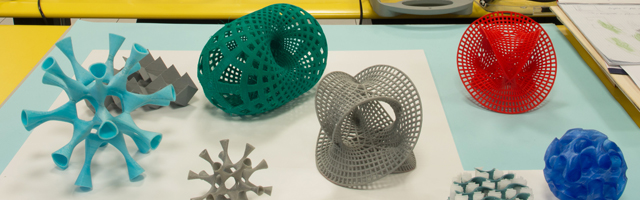

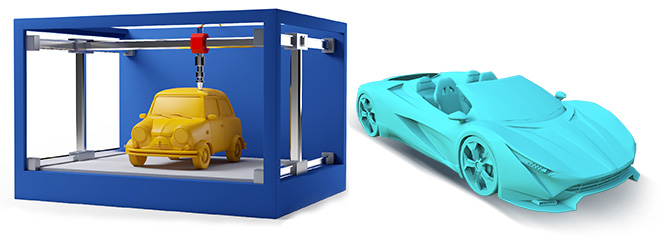

Another term for 3D printing is additive manufacturing. The idea is simply that you can take a 3D model that’s built-in a computer program or in computer-aided design (CAD) and then a machine can take that model and use liquid or other malleable materials to build a physical version of the model by adding small layers of material one after another in accordance to the model as a guide. Just like a typical ink printer paper creates images by adding one line of color at a time to create a photograph, a 3D printer adds one thin layer of material on top of another in the prescribed shape to create the physical object.

The result is a varied amount of applications and opportunities:

- Rapid Prototyping When 3D printing was first created and implemented, the main application was to create functional, rapid prototypes of new objects, parts, and designs.

- Physical Design Communication Rather than have to create a whole manufacturing line that was capable of creating a given ‘widget,’ 3D printing allowed you to take a computer model and create a physical form faster and more cheaply than ever before.

- Architectural Models Using 3D models, architects could more accurately create physical 3D models of their designs and replace the cardboard and glue process that would take many more hours previously.

- Replacement Parts 3D printing allows for the rapid creation of parts that can actually be used in machines, to repair and fit into broken machines, and more.

Industrial Application of 3D Printing

In the industrial sector, the applications of 3D printing are arguably the most versatile and cost-saving. While 3D printing can be informative for academic and research purposes, and there is no shortage of fun applications that can be imagined up by someone who simply wants to play with their own designs, the real applications of 3D printing come into focus when looking across the wide swath of industries that see immediate and profitable uses of 3D printing:

- Architecture and Construction When it comes to architecture and construction (AEC), 3D printing allows for building designs to be created in physical models much more rapidly and affordably. Decades ago, architects would use paper and cardboard products to demonstrate their design plans to clients and peers, but 3D printing means the CAD plans for a building can automatically be made a physical model.

- Manufacturing The prototyping process for a new product or machine meant to be a part of the manufacturing process can be one of the most expensive and time-intensive parts of the manufacturing industry. Using a 3D printer, though, prototypes can be created within hours so teams can analyze and improve the design, saving untold millions of dollars and weeks of work to streamline the production process.

- Medical Within the medical field, patients will often need personalized parts to be fit and created for their bodies and their unique needs. Whether that’s to create a false tooth that fits seamlessly in a mouth, a prosthetic limb that matches a person’s exact measurements, or even a stent needed to be precise down to the microscopic scale to be put into vital organs, 3D printing is making these processes much more successful and much less invasive.

- Art and Jewelry The limit of the artist and jewelry maker used to be based on what was practical to build and feasible to create, but 3D printing has literally made it so if you can imagine a given design, then you create it. The only limit for these artists is now the imagination itself.

- Chemical The chemical industry is open to much experimentation and a fast-paced environment where new tools, containers, and ideas are needed constantly. Using 3D printing, the necessary machines, their unique parts, and anything else necessary for the study and furthering of chemical science are right at your fingertips using a 3D printer.

- Aeronautics and Space The future of manned space travel was completely reinvented when 3D printers became compact enough to send up in a space shuttle or to the space station, as any part or tool that could possibly be needed was able to be created to exact specifications, without spending the untold fortunes to get the exact right part up and into space. 3D printing can help create parts to fix something that went wrong, generate new tools that had never even been designed before, but whose designs are beamed up from Earth, or even a future of 3D printed food on space shuttles could be possible.

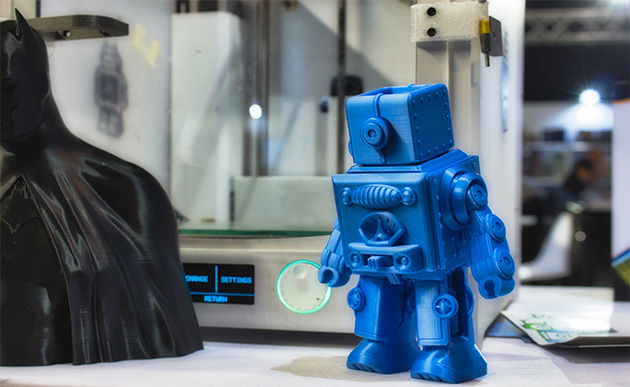

- Robotics Using open-sourced code, 3D printing allows everyone from curious students to world-famous scientists to access the same robotic parts and technologies needed to advance the world of robotics. Parts or entire designs can be rapidly prototyped; robotic enthusiasts need not be restricted by commonly made parts and more.

- Industrial Goods For anyone working in the production of industrial goods, downtime caused by broken parts can mean a huge amount of lost time and money. But with the advancement of 3D printing, those working in industrial goods are now readily able to print out their own replacement machine parts immediately and keep production going.

- Automotive Similarly, anyone working on cars knows the frustration of not having the specialty tool or part that you need and the delays that can cause the project. Not only that, but aesthetic updates and upgrades to the interior and exterior of cars will often require highly customized parts. 3D printing makes both of these processes much faster.

- Education There’s no better way to educate someone on various science, technology, and engineering topics than having them be able to design and print out their own products, parts, tools, and more. Education in these areas and others are open up to outside the box thinking teachers in brand new ways with 3D printing.

Commercial Benefits of 3D Printing

As an enterprise, once you integrate the possibilities of 3D printing, it will be hard to imagine a world before you did. There are so many readily available commercial benefits that you’ll never want to pass up again:

- Customization: The biggest benefit of 3D printing as a part of any industry is the advent of customization on a scale never before imagined. You no longer need to be restricted to parts and machine types that are commercially sold everywhere but can customize exactly what you need.

- Rapid Deployment: Not only can you make custom parts and designs, but you can go from design to physical representative faster than ever before, in mere hours as opposed to weeks or even months required by traditional methods.

- Cost-Effectiveness: By cutting down on time needed, the specialized tools, and the capital-intensive machines, most industries can see their part production and deployment be much more cost-effective than previously imagined.

- Iterative Processes: Because the process from design to production is so much cheaper and quicker, that allows designers to be more iterative and identify and implement improvements to find the best possible design, which would have been impossible in the same timeframe and cost point as with 3D printing.

- Versatility: Lastly, 3D printing just allows for a level of versatility and flexibility that no industry was ever really able to enjoy previously. Designs can change on the go; production can start and stop immediately, and more.

Contact IndiaCADworks for Making Use of 3D Printing

Even though 3D printing is more accessible and available than ever before, both on a space and a cost basis, there are still technical hurdles required to learn what 3D printers can do and how to do it. Especially for smaller enterprises that might not be ready to invest in the 3D printing equipment necessary, deciding to integrate 3D printing is a big decision. But you can always outsource the technical knowledge and the physical implementation of 3D printing practices to IndiaCADworks (ICW) and our wide range of services that cater to industries across architecture, construction, technology, manufacturing, and more. With almost two decades of experience in 3D printing, 3D CAD modeling, reverse engineering, and more, ICW has seen the industries evolving over the years, and we can help you make use of today’s available advanced software and technologies.

Get in touch with us today to schedule a free consultation and learn how we can empower your business to utilize the benefits of 3D printing.

-India CAD works