The use of Computer-aided Design technology in dentistry has had a checkered history due to its low acceptances by fellows in the dental community and the economic recession that hit most parts of Europe and North America—including the United States—did little to foster CAD use by fellows in the dental community.

But the recent recovery of the world’s economic situation, coupled with the advancement of CAD/CAM—computer-aided manufacturing—technology has triggered a new wave of interest from dental clinics, research facilities and dentists about the capabilities of these software drafting tools and how they can be used to simplify dental procedures/design dental restorations. This recent interest has been spiked by the mass production of Chairside systems which come at affordable prices as well as the recent influx of more developing firms designing CAD systems for the dental industry.

According to Brady Baker—MRG analyst, the dental industry in Japan the United States will account for a majority of CAD systems purchased due to the competitive health care atmosphere witnessed in these countries. He says that the need for dentists to carve out a niche for themselves as well as secure a marketing advantage over competing colleagues will be telling point in future sales figures.

CAD developers such as Sinora, 3Shape, Renishaw, and Planmeca now offer the public with chairside systems which are easily affordable and intuitive enough to fit into the medical process of most dentists. The steep learning curve associated with the use of earlier versions of computer-aided design software has also been eliminated and users can now educate themselves on its use with little or no difficulty. And for those who do not have the time and fortitude to learn how to utilize these software tools, outsourcing CAD designs to professionals can also be considered as an option. These positives led the Millennium Research Group to predict a strong growth for the CAD/CAM market in the next three years.

The Unsung Benefits of CAD/CAM Systems in Dentistry

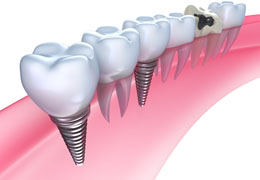

The tradition methods of sculpting dental restorations such as: crowns, veneers, inlays, and dental implants generally lead to material waste as well as the occasional inaccuracies that occur due to human errors. With the use of CAD, these issues are relegated to the background due to the high-level of precision that can be achieved with these systems.

Combining 3D printing—which is also a form of CAD technology—into the dental restoration process, is an easier way of designing and developing dental restoration/implant devices. These tools can be used simultaneously to develop accurate implant prototypes as well as simulate the process of the actual medical procedure to patients who might be interested in learning more about the procedures they might undergo.

Simulations of dental procedures can also be used for developing marketing materials—both video and store dummies—for advertorial purposes as well as for reasons pertaining to professional development.

For more details on the revenue information, cost and market penetration of CAD/CAM software in the dental industry.

– The CAD Chief

IndiaCADworks