Research shows that the 3D printing industry hit record revenues in 2017, with revenues surging past $7 Billion. Over the past few years, additive manufacturing has shown itself worthy for greater volume work. Let’s delve into how that happened and where the manufacturing industry is headed.

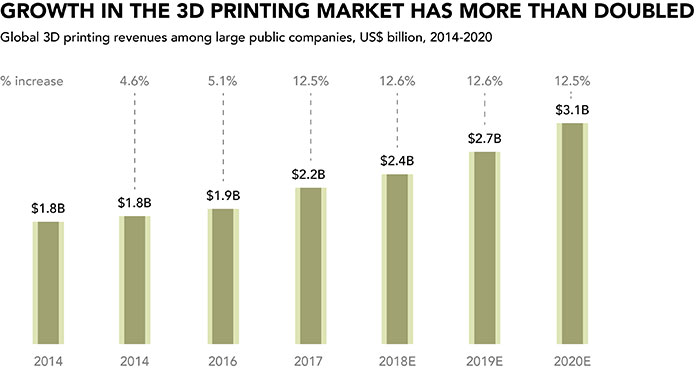

Deloitte Global predicts that sales related to 3D printing by large public companies, including enterprise 3D printers, materials, and services, will surpass US$2.7 billion in 2019 and top US$3 billion in 2020.

3D printing is definitely growing in popularity, because they are capable of printing a greater variety of materials, including metal, faster than they used to.

Not only are 3D printers getting faster, but the printable objects’ size is growing too. A few years ago, a printer could only create objects smaller than 10 x 10 x 10 centimeters. In 2019, we have an improved size of 30 x 30 x 30-centimeter volume! This allows for larger objects to be made without needing to print smaller objects and then assemble them.

3D Printing vs. Traditional Manufacturing

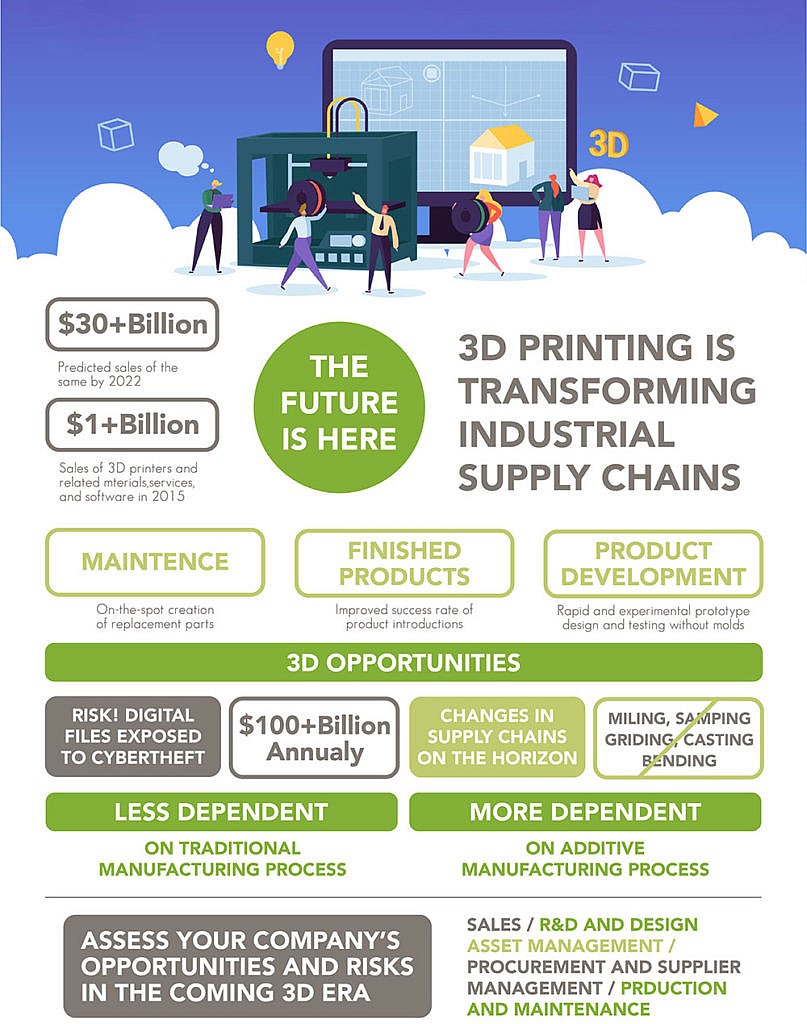

While the concept of 3D printing has been around for a while, advancements in the technology have started to lower the cost of the process, to levels that make it more accessible. However, the question remains, will 3D printing truly replace more traditional methods of assembling products? To answer this, let’s compare the models.

The 3D printing process generally doesn’t require any special new tooling to make a part. If the prototype needs a rework, a new design can be created relatively fast. A traditional assembly line, on the other hand, would much more time to retool the line, wasting time, material, and labor.

With a 3D printer, the only material consumed is what passes through the printer. As an example, in traditional assembly, perforated sheet metal production will cut holes into the whole sheet, leaving a lot more scrap to recycle.

While 3D printers might not need to be retooled in between production runs, they run at a slower speed in comparison to the traditional assembly line. As 3D printing requires each object to be assembled one layer at a time, it cannot currently compete with traditional manufacturing’s speed for mass production.

3D printing can now be used to make objects out of some metals, as well as polymers. However, should the business require other materials, they could be limited in this regard.

With 3D printers, there is a restriction on the total area of the printing bed. Depending on the model of 3D printer you use, this could be a few cubic inches or a few cubic feet. While they can allow you to create a part in pieces for later assembly, doing so may not be ideal.

So, while the use of 3D printing isn’t likely to completely replace traditional manufacturing any time soon, the technology does have incredible utility for small, specialized, one-off production runs.

Subtractive Manufacturing, Injection Molding, and 3D Printing

While additive manufacturing adds successive layers of material to create an object, subtractive manufacturing, does the opposite. Subtractive manufacturing removes sections of material by machining or cutting it away. It can be carried out manually or by (CNC) machining.

One of the advantages of subtractive manufacturing is the ability to machine an extremely thin piece of plastic into a living hinge. This kind of process is simply not yet possible in a 3D printer. For those prototypes that require living hinge components, it is useful to produce certain parts using additive manufacturing, while using the CNC machine for specialty components like a hinge.

Injection molding, on the other hand, can be an effective technology for pre-production prototypes, but generally, it’s used for final manufacturing. The advantage – you can manufacture your prototype in the final material. It is also much more efficient in terms of time to use injection molding when you’re creating more than several dozen copies of a product. Costs might be higher initially to use an injection molding machine, but the more you produce, the more cost-effective it becomes.

The Role of 3D Printing in the Manufacturing Process

3D printing is having a revolutionary impact on product design and manufacturing, particularly in the prototyping phase.

Designers can get their prototypes produced locally and immediately, without any tooling. Prototypes can be easily modified too, allowing designers to take risks and make mistakes early in the design process without incurring hefty costs or delays in production. This also allows designers to get feedback from customers early on. By the time the product is ready for full production, all the kinks have been worked out and fully tested.

Recapping the Advantages of 3D Printing

- Speed Where in the past it may have taken days or even weeks to receive a prototype, additive manufacturing places a model in the hands of the designer within a few hours.

- Cost Machine, material, and labor costs are reduced. For the production of prototypes that verify form and fit, it is significantly cheaper than other alternative manufacturing methods and is often competitive for manufacturing one-off functional parts. Traditional manufacturing techniques become more cost-effective as volume increases, and the large volumes of production justify the high setup costs.

- Quality Additive manufacturing machines complete a build in one step, with no interaction from the machine operator during the build phase. The ability to produce a part in one step greatly reduces the dependence on different manufacturing processes (machining, welding, painting) and gives the designer greater control over the final product.

- Flexibility The ability to create shapes that could not previously be manufactured either as a single part, or at all. Such as hollow cavities within solid parts, parts within parts

- Accessibility: While still not cheap, 3D printing systems can be much more easily obtained and used by a much wider range of people than more traditional manufacturing setups. Additionally, 3D printing is almost completely automated, and requires little to no additional employees to run, supervise, and maintain the machine. This makes 3D printing much more accessible than other manufacturing systems by a long run.

- Sustainability 3D printing means less of an environmental impact created by shipping things across the globe, less waste material for a single part.

3D Printing with IndiaCADworks

While 3D printing does have very many advantages, it can be an expensive and timeous endeavor for a business to take on in-house. This is why it is important to partner with the right outsourcing partner to combat these possible issues.

IndiaCADworks is a global outsourcing provider of CAD services support for mechanical, structural, architectural, and civil engineering verticals. Our team of CAD expert includes more than 80 full-time employees that include experienced engineers and certified CAD drafters.

3D printing services supplied by IndiaCADworks help both individuals and 3D printing companies without hiring new employees. Our exclusive and custom 3D Printing services are readily adaptable to time-sensitive client needs. Speak to us today to discuss the ways we can help enhance your manufacturing speed through 3D printing.

– IndiaCADworks

IndiaCADworks