In the present age of rapidly computerized applications and CAD product designs, it is very likely that many future electromechanical products will have an embedded processor within them. Consider these two examples:

Several decades ago, the automobile industry designed automobiles with carburetion technology. This was being replaced by computer-driven electronic ignition systems. Likewise, manual braking was replaced by computer-assisted “antilock braking.” Recently, the concept of a computer-operated driverless car was mentioned as becoming a real possibility. The idea is not too far-fetched when you consider that computer-managed airplane navigation is a mature technology.

Many products, such as copying machines, refrigerators, HVAC systems, and robotic systems, provide real-time electronic communication between the customer and the manufacturer. For example, downtime for copying machines is significantly reduced because the product is proactive in sensing impending failures and calling for service. This makes the customer believe that the product is very reliable and virtually failure-free.

These two examples illustrate the trend in product development, which combines CAD hardware design, embedded computer technology, and IT (Information Technology) into a package that changes a “dumb product” into a “smart product.” A smart product, therefore, communicates with both its manufacturer and its customers in a manner that improves the functionality of the product and provides optimum performance of the product.

What Are Smart, Connected Products?

There is no known official definition for smart product design. However, a smart product could be defined in terms of these attributes:

- It combines a physical product with its non-physical attributes into one entity. For example, a cellular phone includes a processor or computer which processes information between the phone and the outside world via emails, text messages, browsing the web, capturing and processing images and videos, and providing its location via a GPS tracking system.

- It provides information to the manufacturer about its functionality as well as diagnostic information when the object or product needs servicing or repair. It also provides useful marketing information to the manufacturer.

- Its functionality can be tailored to the customer.

- The product is not defined merely by its physical attributes. Often, its functionality depends strongly on its communication with components and objects outside itself.

A good smart product will have the capability to function when its communication with its outside environment is broken.

For example, an airplane should fly either on autopilot or under the direction of the flight captain. A smartphone should perform its primary function: make and receive phone calls, even if its other smart-phone activities are turned off.

An article in the Harvard Business Review said the following about smart, connected products:

- “Smart, connected products offer exponentially expanding opportunities for new functionality, far greater reliability, much higher product utilization, and capabilities that cut across and transcend traditional product boundaries. The changing nature of products is also disrupting value chains, forcing companies to rethink and re-tool nearly everything they do internally.”

- “Smart, connected products raise a new set of strategic choices related to how value is created and captured, how the prodigious amount of new (and sensitive) data they generate is utilized and managed, how relationships with traditional business partners such as channels are redefined, and what role companies should play as industry boundaries are expanded.”

- “Embedded sensors, processors, software, and connectivity in products (in effect, computers are being put inside products), coupled with a product cloud in which product data is stored and analyzed, and some applications are run, are driving dramatic improvements in product functionality and performance.”

How is Smart Products CAD Technology Important?

Many top CAD design software companies such as SolidWorks® and AutoDesk® provide capabilities for creating a smart product design. Other CAD-related technologies also make it possible to create a smart product design. Listed below are some of these CAD-related technologies:

- 3D solid modeling and rendering, or 3D parametric technology

- Integration between CAD systems and production engineering such as BIM (Building Information Modeling), and the use of IFC (Industry Foundation Classes)

- 3D printing

- Robotics

CNC (Computer Numerical Control) machines.

Product Development Needs to Evolve to Support Today’s Products

As mentioned, smart and connected technology can serve to make the production and design of products easier, but by integrating these characteristics into the final design, they can be more useful and optimized products for the end-users. CAD tools today can integrate smart product design, as you will want your product to take advantage of increasingly prevalent tools that your customers are already fluent in:

- The cloud for data processes and storage

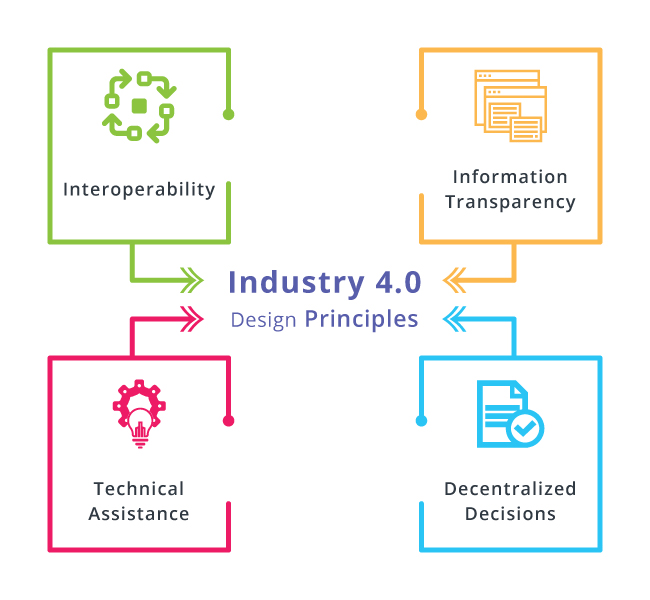

- The Internet of Things for interoperability and communication

- Connected and algorithmically learning tools and solutions

Integrating smart connected aspects to your product early in the CAD and a general inspiration stage is no longer a unique approach, it’s more and more becoming a necessary step for any product development. Don’t be left behind and be sure to utilize smart product CAD technology along the way.

What Could Smart Products Become Commonplace Shortly?

Just as CAD technology does not yet have a unified language or data format, smart product design has no defined standard. Although the practice of smart product design is fragmented, the consumer can confidently expect most future products to become smart products. Here are a few examples:

- A grill that is cooking hamburgers or chicken in the garage can pop up a message on your phone or on your TV to let you know that the cooking is done.

- You could have a robot at home to which you issue the command to take out the garbage or to start preparing your evening meal before you get home.

- Automobiles may soon communicate with one another so that an automobile that is tailgating you will automatically be slowed down by its onboard computer. A vehicle that is traveling at 80 km/hour in a 40 km/hr zone will automatically be slowed down by its onboard computer, and the incident could automatically be reported to law enforcement.

- Medical care may soon use robotic nurses for performing routine tasks, and the patient monitoring system will only call resident nurses for help, which only humans can provide.

- Worn medical devices may soon feed your real-time health information to your physician so that he/she may provide you with timely medical care before viral infections and diseases do too much harm to your body.

- Security procedures at airports may soon use advanced robotic systems, other smart products, together with information about travelers (obtained from intelligence databases), to perform more efficient and non-invasive screening.

Two things are clear.

- More smart products will emerge as a result of the next wave of progress in CAD technology, embedded computer technology, cloud data storage, satellite communication, and IT technology.

- Smart product technology could become a well-defined discipline, like CAD technology.

Why are CAD connected products important?

In the modern world of engineering and design, CAD is like second nature. Even better, the availability and ease of capturing, analyzing, and utilizing data are redefining everything about technology. By combining these two concepts by ensuring you are working within CAD connected products, you can achieve way more than was previously possible, and so CAD connected products are of critical importance.

Engineering teams might be spread out in different locations across the country or the world, so staying connected and working collaboratively is made much easier via CAD connected products because data can be collected in the field and immediately streamed to the relevant design teams to optimize the process and the final design.

Further, these connections across the Internet of Things (IoT) mean you can not only collect that data, but interpret it, integrate it, and make the most of it. IoT access not only makes designing a product easier and more powerful but when that final design has an eye towards IoT use cases for the end-user, then you will be creating innovative products customers will clamor for.

CAD product designs that take place within a connected program also allow those designs to be utilized in virtual reality (VR) and augmented reality (AR). These new worlds allow you to literally walk through your designs and understand spatially how they would look and feel before ever creating them.

The last way that CAD connected products can make life easier for the designer is 3D printing and additive manufacturing. Creating 3D models in CAD and CAE programs is now only a first step, as affordable and quick 3D printing technologies are becoming ubiquitous. With smart products CAD technology, you can seamlessly send your design to be printed for a rapid and inexpensive prototype or any other use.

Harnessing data across domains

When approaching smart connected products and CAD product designs, a real advantage can be the interoperability of data across different platforms, languages, programs, and domains. While your in-house operation and maintenance equipment may collect data in one specific format, being able to utilize smart connected products to translate and utilize said data in another program entirely could bridge the gap, so a series of separate smart products become a whole integrated smart system.

Such harnessing of data across domains requires a good deal of forethought, taking into account the data types different areas of the organization need, and what future needs may arise. But by integrating forward-looking data methods in your smart product design, you can utilize smart connected products to their full potential, and those considerations should come into play early in the design and CAD process.

How CAD Product Designs Are Transforming Companies

Beyond just enabling more interconnected and smart products to be manufactured, the very basis of companies and their operation is being transformed by such products. The technological tools issued to employees are coming with smart and connected characteristics by default, recognizing the value of allowing a heightened level of communication, collaboration, and more.

For example, employees who now live and work hundreds or thousands of kilometers away can brainstorm and collaborate like they were right next to each other, reducing the friction that can get in the way of getting the job done. Further, stacking new connected technology on each other can serve to make every employee more efficient by eliminating wasting time. All employee data and files can be stored in the cloud, connected to whatever machine they happen to be working on, easily shared across the globe with whoever their peers or clients are.

Taking it a step further, bosses in this new type of company are much more easily able to track and watch the progress and development of their employees. Time tracking tools, productivity measurements, and more make the process of assessing the performance of an employee that much easier. Accountability is of utmost importance, and by CAD product designs, companies are harnessing these capabilities.

-IndiaCADworks

IndiaCADworks